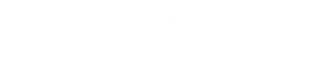

2D-heterostructure transfer system

The 2D-heterostructure transfer system allows the transfer of exfoliated layered materials onto surfaces of various substrates and consists of fully motorized micro-manipulators with a total of 8 degrees of freedom and operate under a high resolution microscope with variable substrate temperature (from room temperature up to around 150ºC). The system includes:

- Sample unit: Three degree of motion (Translation (x,y), Rotation (360º))

- Transfer unit: Five degree of motion (Translation (x,y,z), Goniometer (x,y))

- Microscope (DP23): High resolution microscope Long working distance objectives (5x, 10x, 20x, 50x)

- Sample holder: equipped with temperature control (range RT-120oC) and vacuum hole for affixing sample. Goniometer control allow alignment of glass slide

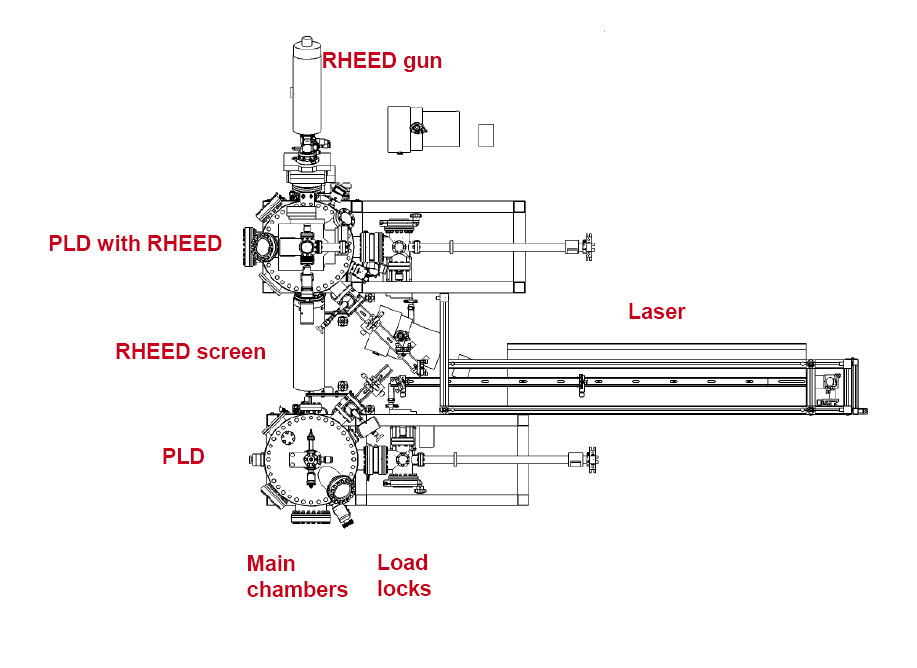

Figure 5: Sketch of the PLD laboratory at ICMAB. In 2012 the PLD chambers will be integrated in a cluster with other chambers.

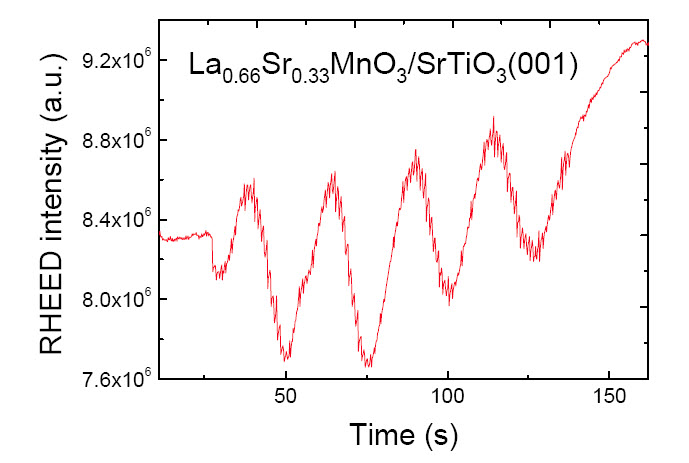

Figure 5: Sketch of the PLD laboratory at ICMAB. In 2012 the PLD chambers will be integrated in a cluster with other chambers. Figure 6: RHEED monitoring of layer-by-layer growth of around 4 monolayer La0.66Sr0.33MnO3 film on SrTiO3(001).

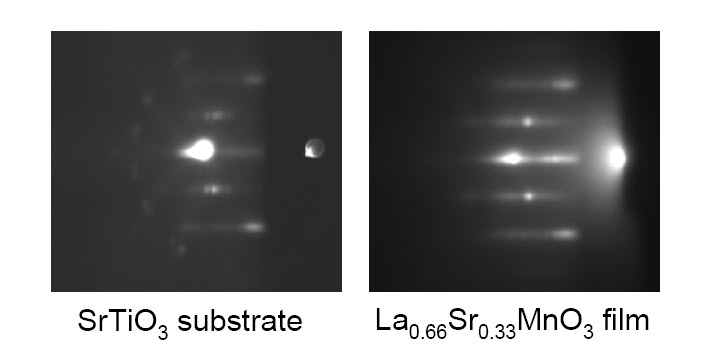

Figure 6: RHEED monitoring of layer-by-layer growth of around 4 monolayer La0.66Sr0.33MnO3 film on SrTiO3(001). Figure 6: Patterns of substrate and film

Figure 6: Patterns of substrate and film